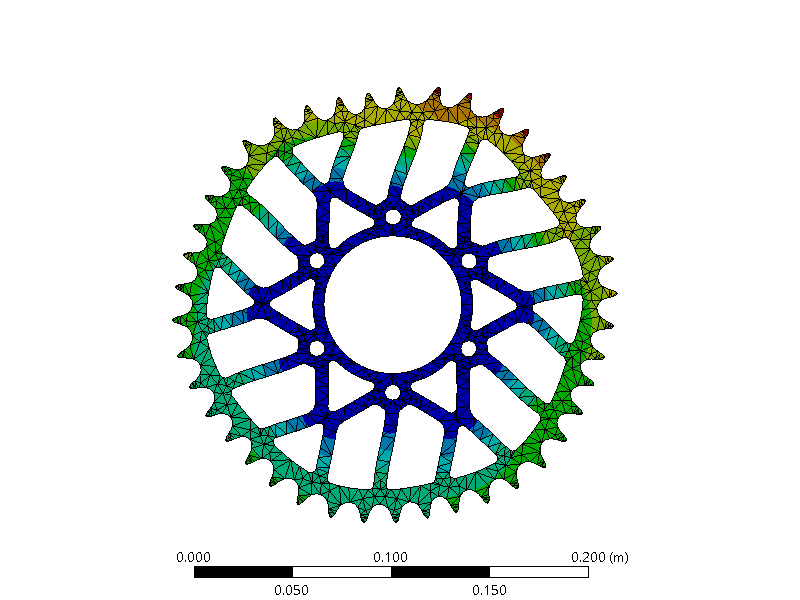

42 Tooth Sprocket Design

Custom sprocket design for high-torque racing applications

Role

Designer & Engineer

Year

2023

Tools

SOLIDWORKS

Project Overview

This project involved designing a custom 42-tooth sprocket for the UTFR racing vehicle's drivetrain system. The sprocket needed to meet specific gear ratios while maintaining structural integrity under high-torque racing conditions.

Design Specifications

- 42 teeth configuration for optimal gear ratio

- Lightweight design using material optimization

- High-strength construction for racing applications

- Precision tooth profile for smooth power transmission

- Optimized weight distribution and balance

Engineering Process

The design process began with calculating the required specifications based on the vehicle's performance targets. Using SOLIDWORKS, I created detailed 3D models with precise tooth geometry following industry standards. The design underwent multiple iterations to optimize weight while maintaining structural integrity.

Technical Challenges

Key challenges included balancing weight reduction with strength requirements, ensuring precise tooth profile for minimal wear, and integrating the sprocket with existing drivetrain components. FEA analysis was conducted to verify stress distribution and factor of safety under racing loads.

Manufacturing

The sprocket was manufactured using CNC machining to ensure precise tolerances. Material selection focused on high-strength alloys suitable for racing applications. Post-manufacturing, the component was tested for dimensional accuracy and surface finish quality.

Results

The final sprocket met all design specifications and successfully integrated into the vehicle's drivetrain system. The design demonstrated excellent performance under testing conditions and contributed to the overall efficiency of the power transmission system.