Actuator Cable Disengagement Mechanism

Compact service mechanism for jam recovery and latch release under strict packaging and load constraints

Overview

Timeframe: 2024-2025

Institution: University of Toronto - MIE442 (Mechanical Design)

Team Size: 5 members (Sam Bahrami, Kelvin Cao, Clive Fellows, Mo Taban, Batu Tibet)

Role: Mechanical Design and Structural Validation Engineer

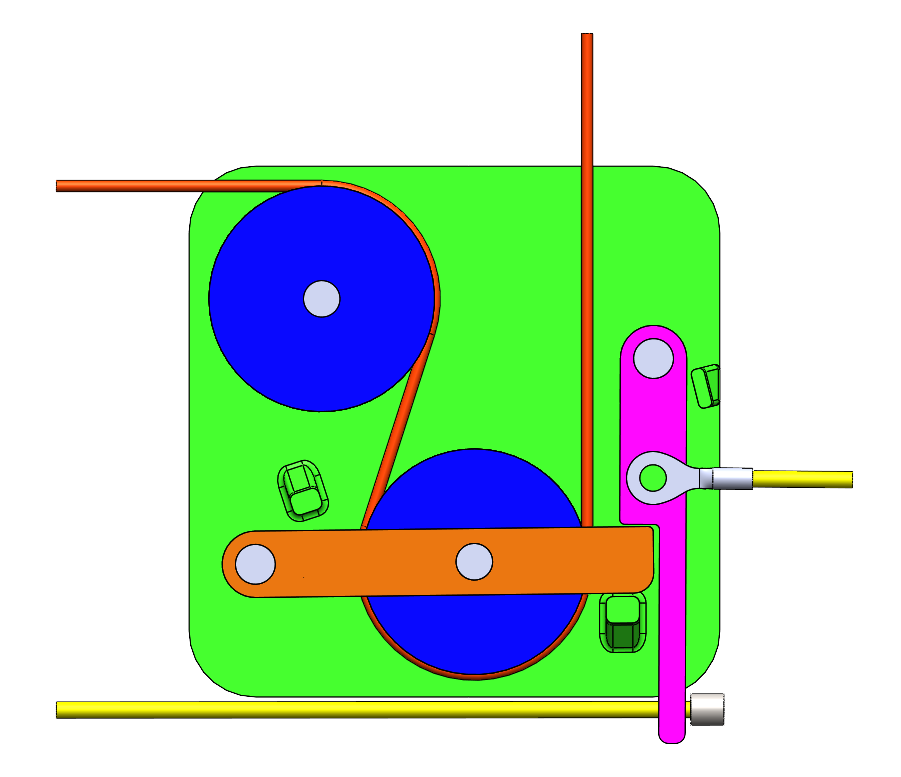

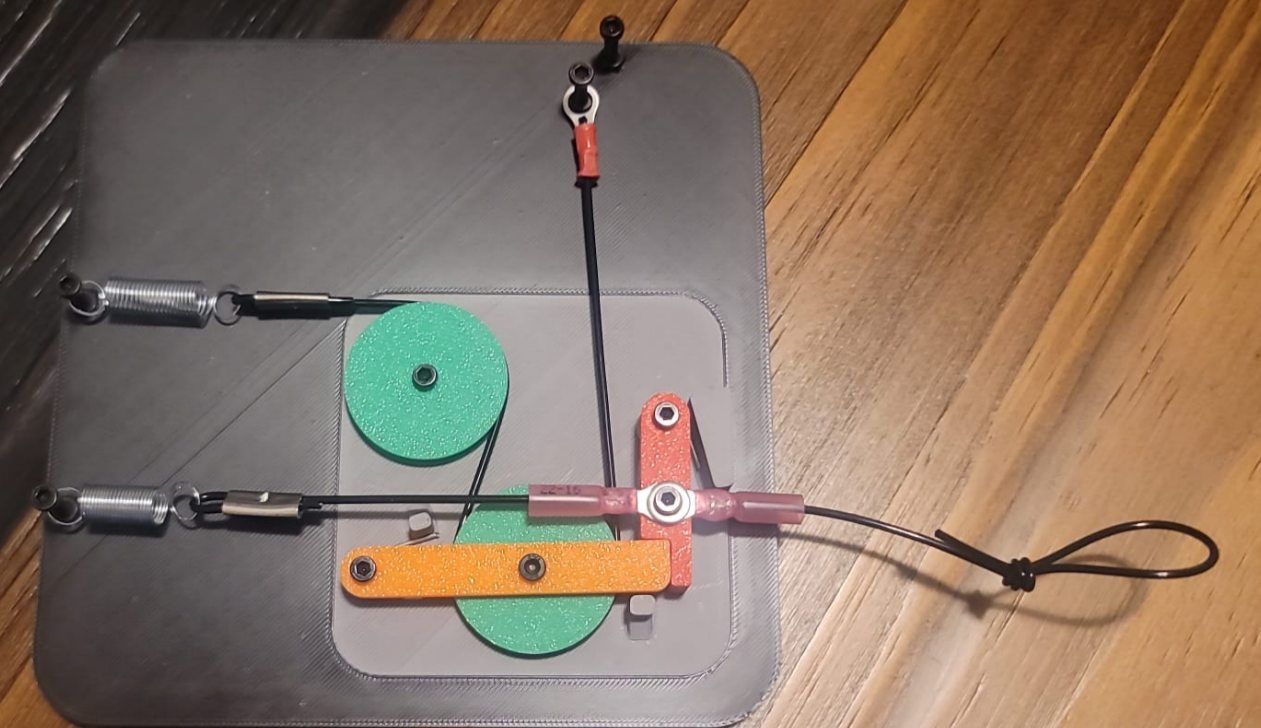

Designed a manual service mechanism that slackens a jammed actuator cable and releases the latch from one pull while fitting within an 80 x 80 x 30 mm envelope and holding a 2.0 safety factor.

The Problem

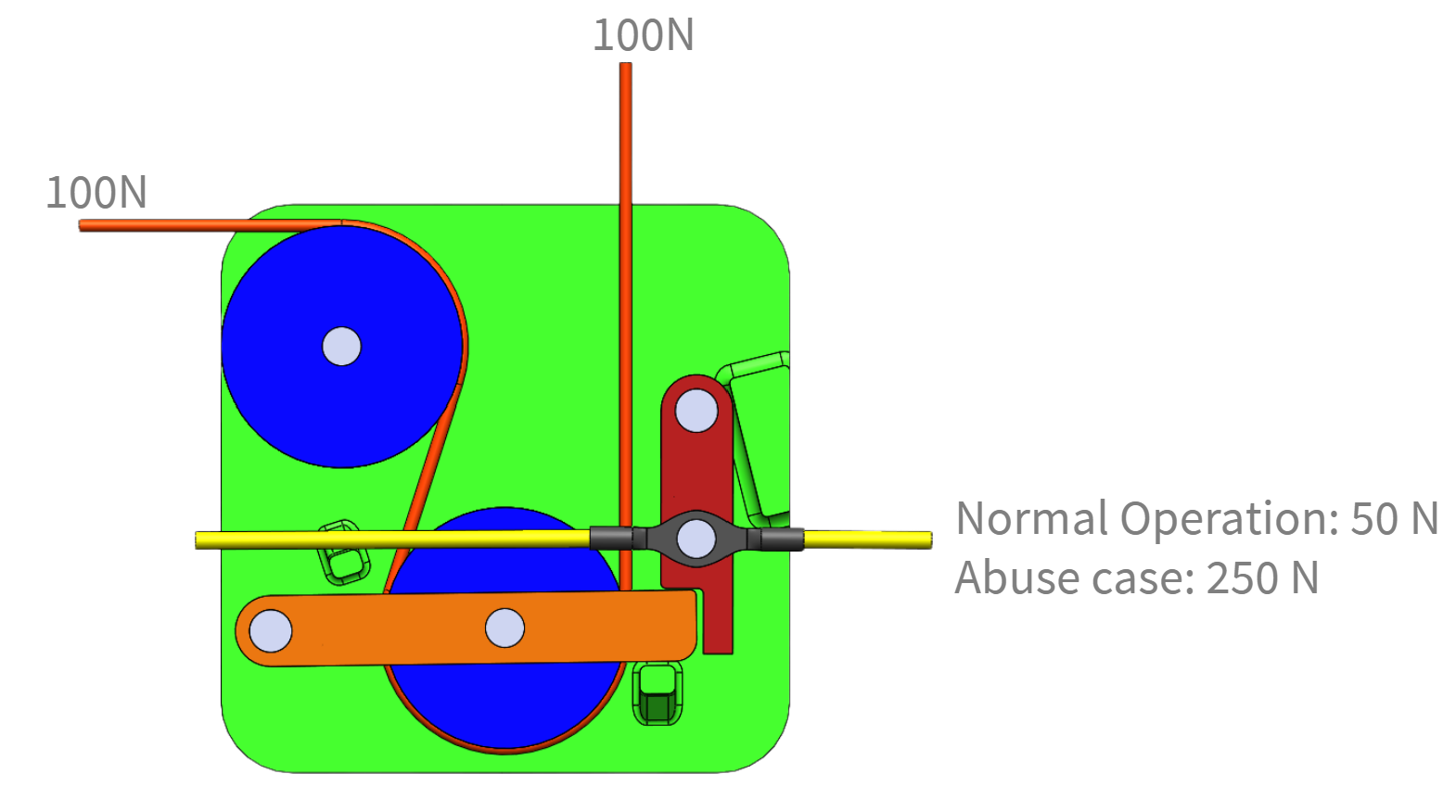

Stalled actuators keep the latch locked by holding cable tension. The mechanism needed to create slack and release the latch with a single input, stay under 50 N pull force, and survive 250 N abuse loads.

Constraints

- 80 x 80 x 30 mm package

- Single 50 N manual pull

- 250 N abuse load with ≥2.0 safety factor

- Repeated service cycles and elevated temperature

- Both slack generation and latch release from one motion

Solution

I led concept and validation work:

- Lever and pulley layout that generates slack and triggers the latch in the same stroke

- Service lever geometry sized for 50 N input and hard stops for repeatability

- Steel pins with polymer housings and torsion springs for reset and durability

- Compact stack-up optimized for manufacturability and tolerance control

Analysis

- Free body and contact stress checks on service, jam, and abuse cases

- Beam and pin stress sizing with Modified Goodman fatigue review

- ANSYS static runs to confirm hand calculations within acceptable agreement

- Iterative geometry tweaks to remove stress concentrations

Tools & Technologies

Design Validation

Results:

- Met the 50 N pull target with margin through mechanical advantage

- Cleared 2.0 safety factor across service and abuse cases

- Validated cyclic life for pins and springs

- Kept the full assembly inside the 80 x 80 x 30 mm volume

Key Learnings

- Hand calculations first made FEA setup faster and more trustworthy.

- Tight packaging forced a cleaner architecture that combined functions.

- Designing for manufacturing early avoided costly geometry changes later.