← Back to Projects

Manufacturing Engineering / Fabrication

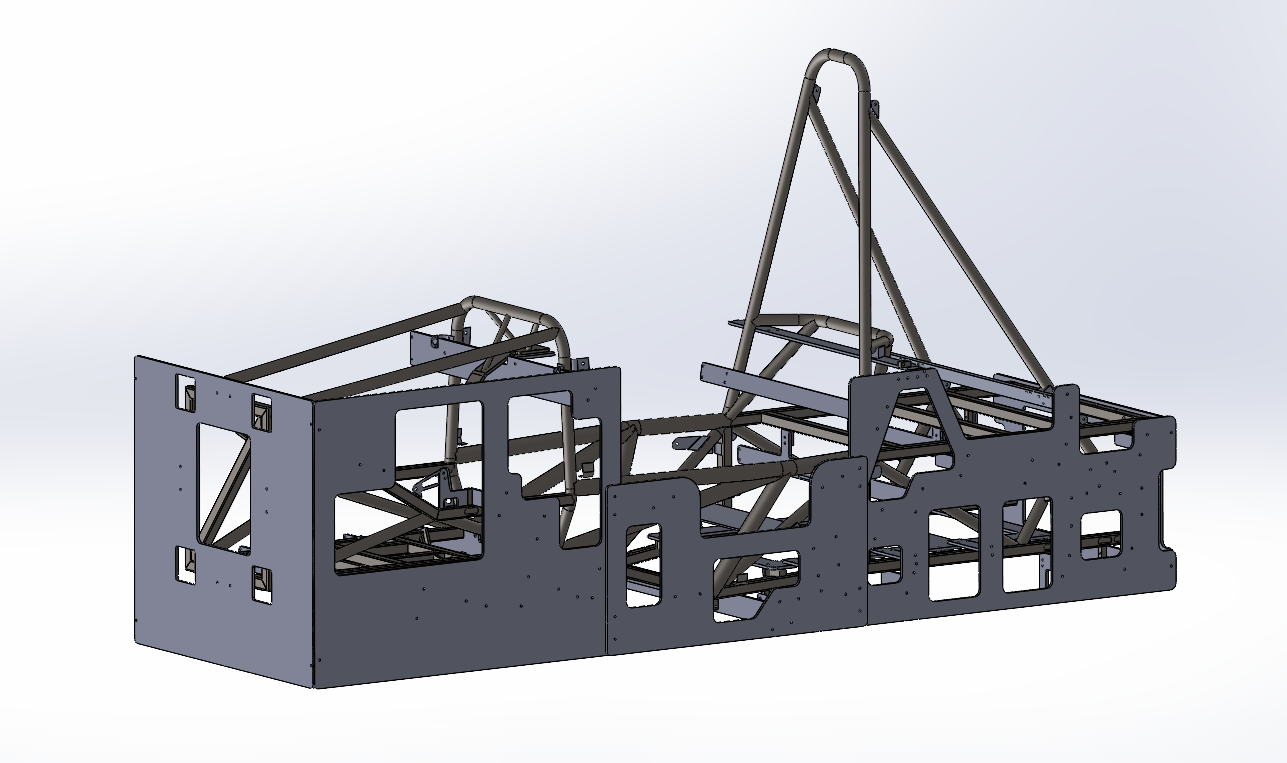

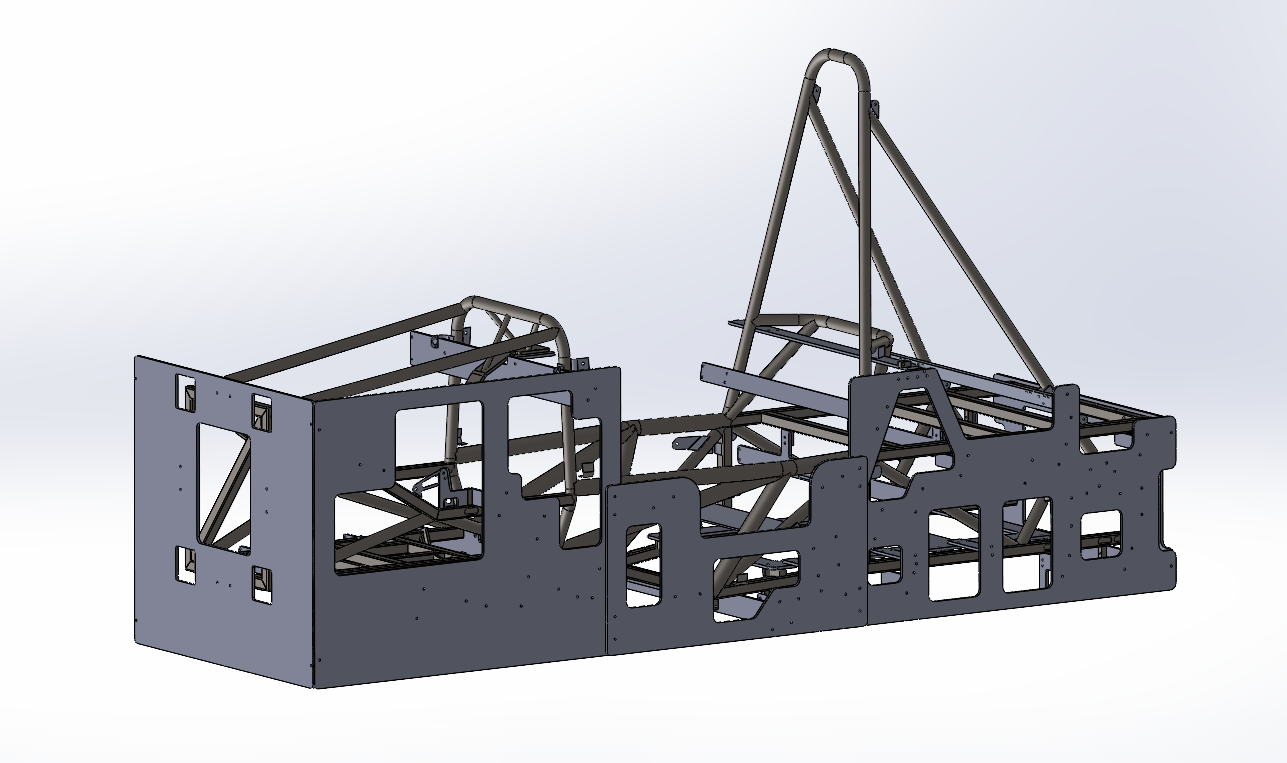

Chassis Manufacturing System, Tooling, and Assembly

Fixtures, process planning, and assembly methods for a student-built FSAE chassis

Overview

Timeframe: 2023-2025

Category: Manufacturing Engineering / Fabrication

Student-built chassis needed repeatable accuracy with limited tools. I created the weld fixtures, tube prep flow, sequencing, and panel interfaces to cut rework.

The Problem

Past frames wandered out of tolerance because fixturing and procedures varied by operator, driving rework and poor fit-up.

Constraints

- Manual tools and student welders

- Competition-driven schedule

- Need for repeatability without expensive jigs

Technical Work

- Designed weld jigs to lock datums and tube locations

- Published cut lists, tack sequences, and weld order to limit distortion

- Created panel interfaces and bonding features

- Tied the chassis build into the overall vehicle plan

Tools & Methods

SOLIDWORKS

Manual Fixturing

TIG Welding

Composite Bonding

Assembly Planning

Impact & Results

10

Weld Jigs Designed

100+

Structural Welds

Result: tighter fit-up, less rework, and faster builds because every operator followed the same fixtures and sequence.

Process & Assembly Planning

Datums, gauges, and tack sequences were defined up front so the frame stayed aligned through welding and panel bonding.

Key Learnings

- Simple jigs that constrain the right datums beat complex fixtures.

- Clear work instructions reduce variation more than extra tooling.

- Upfront process design saves the most time at final assembly.