← Back to Projects

Vehicle Structures

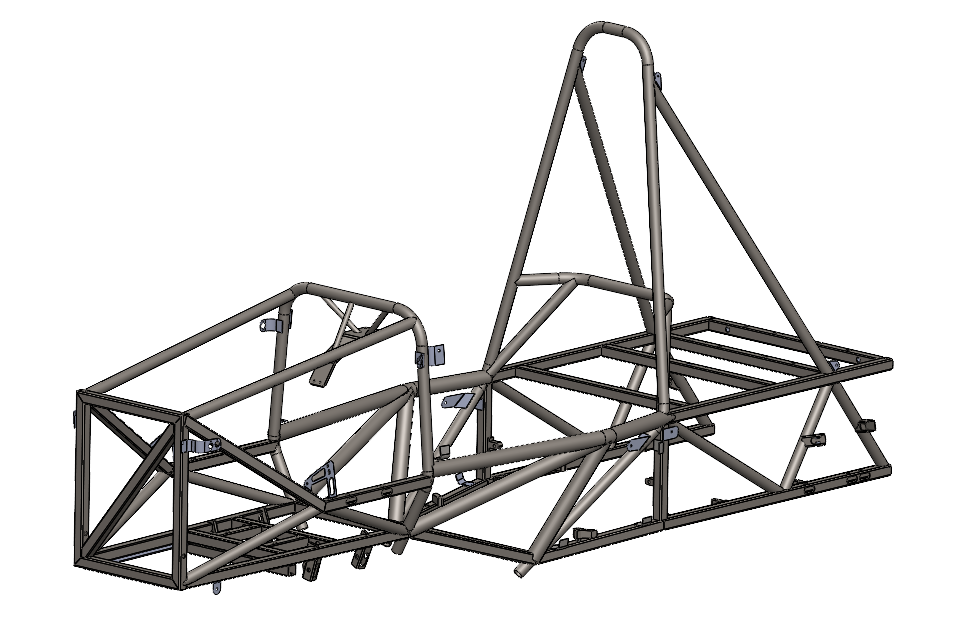

Formula SAE Chassis Structural Architecture

Optimized tubular spaceframe design for electric race car

Overview

Timeframe: 2025-2026

Category: Vehicle Structures / Mechanical Design

Designed a tubular spaceframe for a Formula SAE EV, balancing stiffness, safety, manufacturability, and aggressive mass and cost targets.

The Problem

The baseline frame was heavy and inefficient, with tubes that added mass but little stiffness. It needed a clean redesign that stayed rule-compliant and easy to build.

Constraints

- Formula SAE rules and impact requirements

- Known suspension and drivetrain load cases

- Student welding and simple fixtures

- Strict mass and cost targets

Technical Approach

I led the structural layout and sizing:

- Defined load paths, triangulation, and joint topology

- Converted suspension and impact loads into frame-level cases

- Sized tubes with hand calcs plus Ansys and MATLAB checks

- Removed non-contributing members and right-sized critical ones

Tools & Technologies

Ansys Mechanical

MATLAB

SOLIDWORKS

FEA Analysis

Load Path Analysis

Design Optimization

Impact & Results

20%

Mass Reduction

74

Structural Members

43%

Cost Reduction

Results:

- 20% mass reduction while holding stiffness and safety margins

- 43% material cost cut through targeted sizing

- Clear, rule-compliant layout that was manufacturable with student tooling

Design Philosophy

Every tube had to earn its place in the load path. Lean triangulation, right-sized diameters, and simple joints kept the frame light and stiff without exotic tooling.

Key Learnings

- Hand calcs plus FEA gave faster, more confident decisions.

- Rule familiarity exposes hidden optimization room.

- Lightweight frames come from deleting unnecessary members, not thinning everything.