← Back to Projects

Mechanical Design

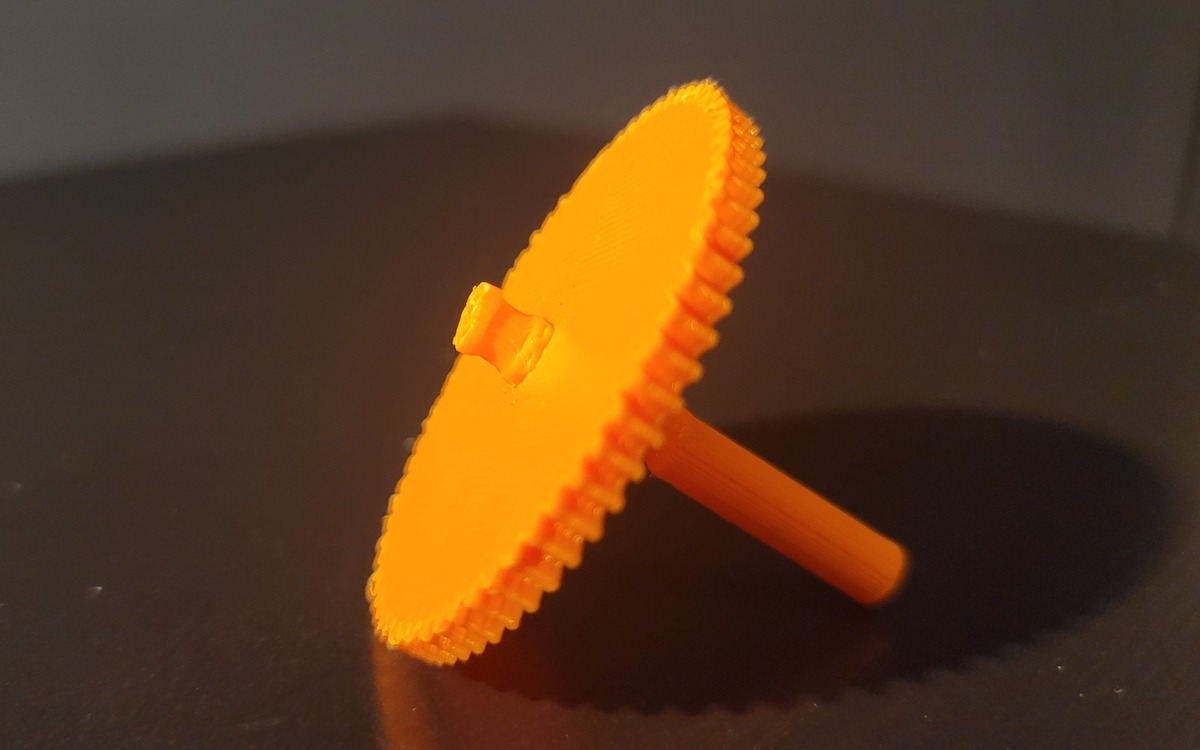

Gearbox Design

Precision gearbox engineering for optimal power transmission

Overview

Conceptual 16:1 reduction gearbox using staged spur gear pairs (4:1 × 4:1) with a compact U-shaped layout for clean power transmission and straightforward manufacturability.

The Problem

Deliver a compact reduction stage with predictable backlash and practical assembly constraints while maintaining serviceability.

Constraints

- Target overall ratio: 16:1

- Spur gear geometry for simplified machining and sourcing

- Reasonable bearing spans and shaft diameters

Technical Approach

- Two-stage spur reduction (16T→64T, 16T→64T)

- Shared intermediate shaft with co-axially mounted gears

- Packaged in a U layout for minimal footprint and straightforward assembly

Tools & Technologies

Mechanical Design

SOLIDWORKS

Gear Sizing

Impact & Results

Clean, manufacturable reduction concept suitable for educational and prototype applications with clear service access and bill-of-materials simplicity.

Key Learnings

Balancing gear sizing, bearing spans, and package constraints early avoids late-stage layout compromises.

3D Model