← Back to Projects

Drivetrain Design

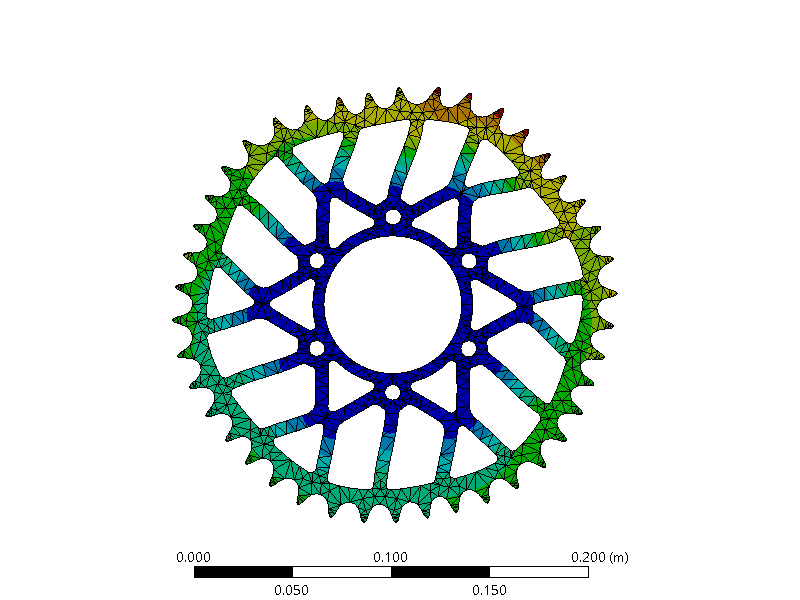

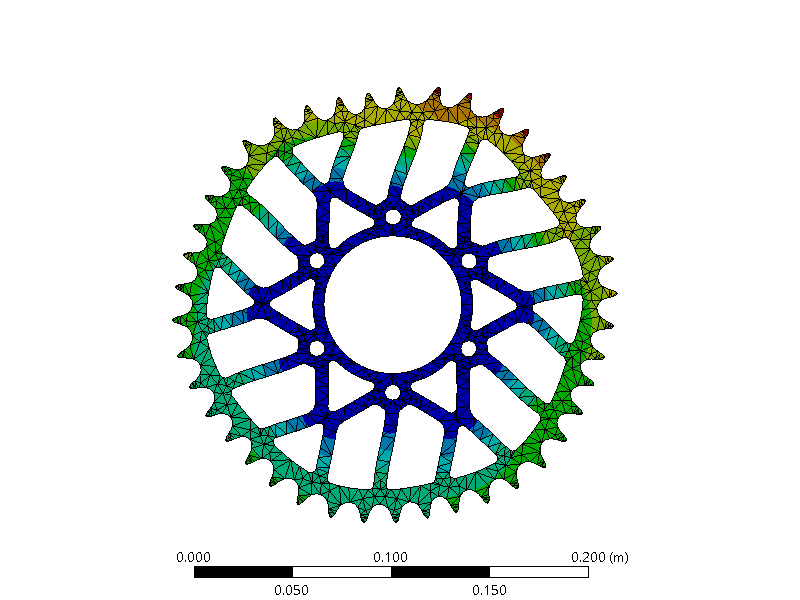

42 Tooth Sprocket Design

High-performance sprocket for electric vehicle power transmission

Overview

Timeframe: 2023

Category: Drivetrain / Mechanical Design

Designed a custom 42-tooth sprocket for the UTFR FSAE EV, hitting the target ratio while staying light and strong for racing loads.

The Problem

Needed a 42T sprocket with smooth engagement, low rotating mass, and enough strength for racing loads; off-the-shelf parts were heavy and wrong ratio.

Constraints

- Fixed 42T, 3.67:1 ratio

- Chain and hub compatibility

- Low rotating mass, CNC friendly, student budget

Technical Approach

- Involute-based tooth geometry for smooth engagement

- Tooth root and hub stress checks to set thickness and fillets

- Web and pocket pattern optimized for mass while staying stiff

- FEA plus CNC-ready drawings for quick manufacture

Tools & Technologies

SOLIDWORKS

Finite Element Analysis

Gear Design

CNC Programming

Material Selection

Mechanical Optimization

Impact & Results

1.2 kg

Final Weight

3.5×

Safety Factor

42

Teeth

Results:

- Lightweight part that kept rotating inertia down

- Smooth power delivery from precise tooth form

- Manufacturing-ready package with validated stresses

Design Philosophy

Remove mass only where analysis says it is safe. Involute teeth, targeted pockets, and validated fillets kept the sprocket light without sacrificing stiffness.

Key Learnings

- Gear fundamentals and stress checks matter even on “simple” parts.

- Manufacturing limits can guide cleaner, faster-to-machine geometry.